S45C Hard Chrome Plated Piston Rod Bakeng sa Pneumatic Cylinders

The pneumatic cylinder hydraulic piston rod e boetse e bitsoa chrome-plated rod.Ke molamu o nang le bokaholimo bo tšoaroang ka ho sila ka mokhoa o khethehileng le ho roala ka chrome e thata.E sebelisoa haholo ho li-cylinders tse fapaneng, li-hydraulic cylinders, liphutheloana, mapolanka, mochini o ohlang, oa khatiso le oa ho daea, likarolo tsa ho lahla le lisebelisoa tse ling tsa phetisetso ea othomathiki ka lebaka la boima ba eona bo ka lelefatsang bophelo ba ts'ebeletso ea mechini e tloaelehileng le lisebelisoa.

Re ile ra amohela serame se batang, ho hlonepha le ho bentša ho etsa molamu oa piston oa silinda ea pneumatic hydraulic, sepheo se seng le se seng sa tekheniki se kopana le maemo a naha.

Tlhaloso ea lintlha

lisebelisoa: CK45(GB/T699-1999)

Tlhaloso ea mochine:

Matla a ho tiea(Mpa):≥600N/mm2

0,2 Yield Stress(Mpa):≥355N/mm2

Elongation:min.16%

Botenya ba Chrome Plated:φ<20mm≥15μm,ho tlohaφ20mm>20μm

Bokhopo: Ra<0.2

Thata ea Chrome Layer:850HV-1050HV

Mamello ea Diameter: f7,f8

Ho otloloha: <0.1um/1000mm

Ovality: < 1/2 bophara ba mamello

Tlhahlobo ea Tlhahlobo ea Corroseston: ISO 10289:1999,IDT

Bophara ba ka ntle: 3-120mm (GCr15) 3-40m(SUS440C)

Boemo ba ho pepa: Tloaelehileng, Induction Harden,Q+T

Tafole ea sebopeho sa lik'hemik'hale

| MOSEBETSI OA K'hemik'hale(%) | |||||||

| Lintho tse bonahalang | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0,50 | 0.50-0,80 | 0.17-0.37 | 0.035 | 0.035 | ||

| ST52 | <=0.22 | <=1.6 | <=0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1,70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0,35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Kr | 0.37-0.45 | 0.50-0,80 | 0.17-0.37 | 0.80-1.10 | |||

| Diameter | Boima ba 'mele | Mamello | Mamello | Mamello |

| mm | Kg/m | f7 (μm) | f8(μm) | h6(μm) |

| 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| 8 | 0.39 | -13--28 | -13--35 | 0--9 |

| 10 | 0.62 | -13--28 | -13--35 | 0--11 |

| 12 | 0.89 | -16--34 | -16--43 | 0--11 |

| 16 | 1.58 | -16--34 | -16--43 | 0--11 |

| 18 | 2.00 | -16--34 | -16--43 | 0--13 |

| 20 | 2.47 | -20--41 | -20--53 | 0--13 |

| 22 | 2.99 | -20--41 | -20--53 | 0--13 |

| 25 | 3.86 | -20--41 | -20--53 | 0--13 |

| 28 | 4.84 | -20--41 | -20--53 | 0--13 |

| 30 | 5.55 | -20--41 | -20--53 | 0--16 |

| 32 | 6.32 | -25--50 | -25--64 | 0--16 |

| 36 | 8.00 | -25--50 | -25--64 | 0--16 |

| 38 | 8.91 | -25--50 | -25--64 | 0--16 |

| 40 | 9.87 | -25--50 | -25--64 | 0--16 |

| 45 | 12.49 | -25--50 | -25--64 | 0--16 |

| 50 | 14.22 | -25--50 | -25--64 | 0--19 |

| 55 | 15.43 | -30--60 | -30--76 | 0--19 |

| 60 | 18.66 | -30--60 | -30--76 | 0--19 |

| 65 | 26.07 | -30--60 | -30--76 | 0--19 |

| 70 | 30.23 | -30--60 | -30--76 | 0--19 |

| 75 | 34.71 | -30--60 | -30--76 | 0--19 |

| 80 | 39.49 | -30--60 | -30--76 | 0--22 |

| 85 | 44.58 | -36--71 | -36--90 | 0--22 |

| 90 | 49.98 | -36--71 | -36--90 | 0--22 |

| 95 | 55.68 | -36--71 | -36--90 | 0--22 |

| 100 | 61.70 | -36--71 | -36--90 | 0--22 |

Litekanyetso tsa mamello ea f7 le f8 ke life:

Mefuta ea mamello ea f8 e kholo ho feta ea f7, 'me ho kenngoa ho itšetlehile ka boemo ba sebaka sa mamello ea lesoba.Ka mohlala, ha boholo ba motheo bo le 10-18, f8(-0.016,-0.034), f7(-0.016,-0.027), kheloha ea mamello e 'meli e tšoana, mefuta ea f7 e nyenyane, le ho hlaka. mefuta e fapaneng ea ho kenya e nyane.

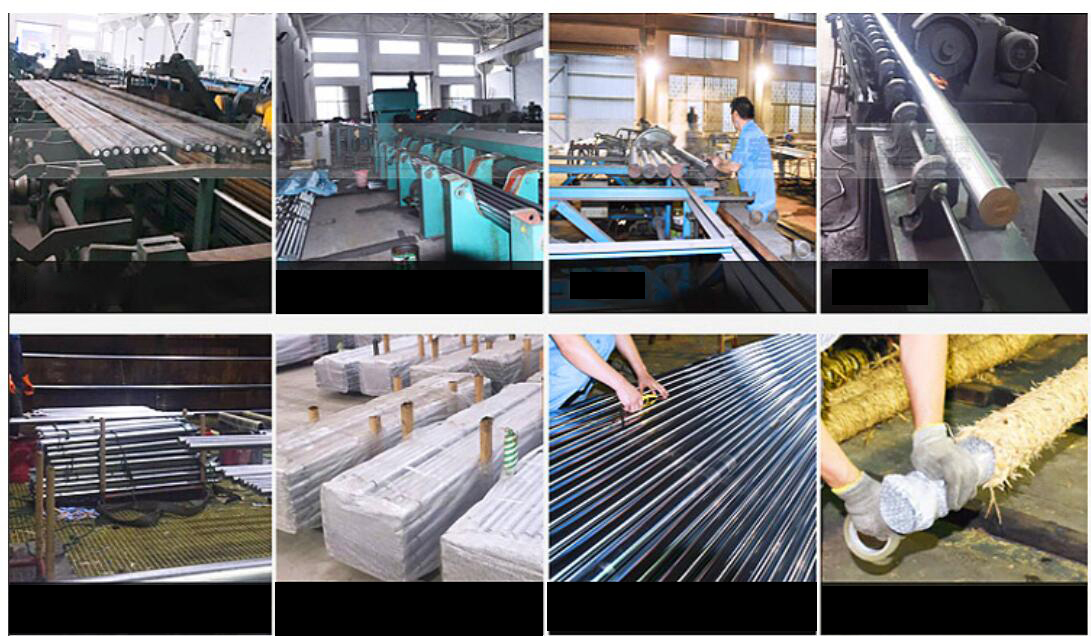

Phallo ea Tlhahiso

Mohato oa 1: Ho ebola / Ho Rata:

Ho taka ka mokhoa o batang ke theknoloji ea ho lokisa ea pneumatic cylinder piston rod.Bakeng sa pneumatic silindara e thata ea chrome plated rod, ho taka ho bata ho bolela ho hula tlas'a boemo ba mocheso o tloaelehileng e le ho finyella sebopeho se itseng le thepa e itseng ea mochine.Ha ho bapisoa le sebopeho se chesang, lihlahisoa tse huloang ke serame li na le melemo ea ho nepahala ha maemo a holimo le ho qeta bokaholimo bo betere.

2 Mohato: Ho otloloha

Mohato ona re ka etsa bonnete ba hore molamu o thata oa chrome o otlolohile ka ho lekaneng.Ho bohlokoa haholo, ha o e kenya kahare ho silindara ea pneumatic.Ho otloloha ho tloaelehileng ke 0.2mm/m.

3 Mohato: Ho hlompha

Honing processing ke mokhoa o sebetsang oa ho sebetsa o nolofalletsang sebaka sa pneumatic cylinder piston rod ho finyella ho nepahala ho phahameng, boleng bo phahameng ba holim'a metsi le bophelo bo bolelele.E ka ntlafatsa ka nepo ho nepahala ha litekanyo, ho nepahala ha sebopeho le ho fokotsa boleng ba Ra, empa e ke ke ea ntlafatsa boemo ba sekoti le libaka tse ling.

Mohato oa 4: Ho bentša lere la tšepe

Ho pholisa ho bolela ts'ebeliso ea litlamorao tsa mochini, tsa lik'hemik'hale kapa tsa electrochemical ho fokotsa bokaholimo ba molamu oa piston ea pneumatic cylinder ho fumana sebaka se khanyang le se boreleli.Ke tšebeliso ea lisebelisoa tsa ho bentša le likaroloana tsa abrasive kapa lisebelisoa tse ling tsa ho bentša ho fetola bokaholimo ba molamu oa piston oa pneumatic cylinder.

5 Mohato: Chrome Plating

Ho roala ha Chrome ho bolela ketso ea ho betla chromium e le ho roala holim'a molamu oa chrome o thata oa pneumatic.

Sekhahla se entsoeng ka chromium se na le boima bo phahameng haholo, 'me boima ba sona bo ka fapana ka har'a mefuta e mengata ea 400-1200HV ho ea ka sebopeho sa tharollo ea plating le maemo a tshebetso.Lera la chrome-plated le na le ho hanyetsa mocheso o motle.Ha mocheso o ka tlase ho 500 ℃, ha ho na phetoho e totobetseng ea ho benya le ho thatafala.Thempereichara e tla qala ho oxidize le ho fetola mmala ha mocheso o ka holimo ho 500 ℃, 'me boima bo tla fokotseha ha bo le ka holimo ho 700℃.Khokahano ea khohlano ea lera la chrome e nyane, haholo-holo coefficient e omeletseng ea likhohlano, e leng eona e tlase ho litšepe tsohle.Ka hona, lera la chrome-plated le na le khanyetso e ntle ea ho apara.

Lera la plating la chromium le na le botsitso bo botle ba lik'hemik'hale.Ha e na phello ho alkali, sulfide, nitric acid le boholo ba li-organic acid, empa e ka qhibiliha ka pneumatic acid (e kang pneumatic acid) le hot sulfuric acid.Ka har'a leseli le bonahalang, ho bonahatsa chromium ho ka ba 65%, e pakeng tsa silevera (88%) le nickel (55%).Hobane chromium ha e fetole 'mala, e ka boloka ponahalo ea eona ka nako e telele ebile e molemo ho feta silevera le nickel.

Bohato ba 6: Molamu o pentiloeng ka Chrome ka mor'a ho roala

Electroplating le polishing: ke mekhoa e 'meli e fapaneng ea ho phekola holim'a tšepe le lisebelisoa tse ling.Ea pele ke phekolo ea lik'hemik'hale, 'me ea ho qetela ke phekolo ea mechine.

Electroplating: Mokhoa oa ho sebelisa electrolysis ho hokela lera la filimi ea tšepe holim'a tšepe kapa lintho tse ling.E ka thibela kutu, ea ntlafatsa ho hanyetsa, ho tsamaisa motlakase, ho bonahatsa le ho ntlafatsa botle ba botle.

Ho hloekisa: Sebelisa lisebelisoa tsa ho bentša tse tenyetsehang le likaroloana tsa abrasive kapa mecha ea phatlalatso ea ho bentša ho fetola bokaholimo ba mosebetsi.Ho pentša ho ke ke ha ntlafatsa ho nepahala ha dimensional kapa ho nepahala ha sebopeho sa mosebetsi, empa ho ikemiselitse ho fumana bokaholimo bo boreleli kapa seipone se khanyang.

7 Mohato: Teko ea Boleng ba Molamu oa Chrome

Lithupa tsa piston tse kileng tsa etsoa ka mokhoa oa electroplating le polishing hangata li tsamaisana le mefokolo ea ho roala joalo ka likoting tsa chrome le likoti.Boholo le bongata ba likoli tsena li ama ka kotloloho ts'ebetso ea molamu oa piston.Ho fokotsa tšusumetso ea likoli tsena holim'a molamu oa piston, ka lehlakoreng le leng, ka ho ntlafatsa boleng ba lisebelisoa tse tala, ho ntlafatsa theknoloji ea ho sebetsa, le ho fokotsa ho hlaha ha bokooa;ka lehlakoreng le leng, hoa hlokahala ho lemoha ka nepo liphoso tsa plating kamora ts'ebetso ea polishing ho qoba lihlahisoa tse sa tšoaneleheng ho tsoa fekthering.Baenjineri ba Autoair ba lemoha bofokoli ba boits'oaro ka thuso ea tsebo ea mahlale a litšoantšo

8 Mohato: Ho paka

LBH:

Q1: Molamu oa piston oa pneumatic cylinder ke eng?

A: Molamu oa piston ke karolo ea bohlokoa le ea bohlokoa ea silindara e 'ngoe le e 'ngoe ea hydraulic kapa pneumatic.Thepa ea piston ka tloaelo ke bolelele bo nepahetseng ba mochini oa chrome e thata e koahetsoeng ka tšepe e batang e fetisang matla a entsoeng ke piston ho karolo ea mochini e etsang mosebetsi.

Q2:Molao-motheo oa molamu oa piston oa pneumatic cylinder ke ofe?

A: Piston ea pneumatic cylinder e ka har'a silinda e jara matla kapa matla a hulang a hlahisoang ke khatello ea moea, 'me e sebetsa ka kotloloho holim'a molamu oa piston oa pneumatic cylinder o hokahaneng le piston, ebe molamu oa pneumatic cylinder piston o hokahana le sesebedisoa sa mojaro ho tsamaea. pele le morao.

Q3: Ke lisebelisoa life tse tala tsa molamu oa hau oa pneumatic cylinder piston?

A: Hangata, molamu oa piston oa pneumatic cylinder o tla khetha 45 # tšepe e le thepa e tala.Haeba moqomo o hlahisoang o hloka ho sebelisoa tikolohong e khethehileng, tšepe e sa hloekang ea 304 e ka boela ea sebelisoa

Q4: Hobaneng u khetha 45 # tšepe e le lisebelisoa tse tala

A: 45 # tšepe ke tšepe ea boleng bo phahameng ea carbon e nang le boima bo tlaase le ho itšeha habonolo.Kamora ho tima, boima ba eona ba bokaholimo bo ka fihla ho 45-52HRC.Hape e ka ba le ts'ebetso e ntle ea ho itšeha le matla a holimo, ho tiea le lisebelisoa tse ling tse felletseng tsa mochini, ka hona ke e 'ngoe ea lisebelisoa tse sebelisoang hangata bakeng sa likarolo tsa shaft.

Q5: Ts'ebetso ea machining ea molamu oa hau oa piston ea pneumatic cylinder ke eng?

A: E le hore u fumane boleng bo tsitsitseng ba machining, ho otloloha ka letsoho ha molamu oa piston ha ho lumelloe ka mor'a hore mochine o qale.Ka hona, ts'ebetso ea ho otlolla e lokela ho etsoa pele ho etsoa machining.Ka lebaka la ho se tsitse ha mosebetsi oa ho sebetsa, ho fetoha ho thata le ho fetola hantle ho tlameha ho etsoa nakong ea ts'ebetso ea machining ho ntlafatsa ho nepahala ha machining.Mokhoa oa ho sebetsa oa molamu oa piston o fetoha motsamao oa mola.E le ho ntlafatsa bophelo ba tšebeletso ea molamu oa piston, bokaholimo bo lokela ho ba chrome-plated ho ntlafatsa ho thatafala ha eona holim'a metsi le ho hanyetsa ho apara.Kamora ho roala ka chrome, kalafo ea polishing e ea hlokahala ho fumana mafika a holimo holimo, ho fokotsa likhohlano, le ho ntlafatsa ts'ebetso ea ho tiisa.Kaha ts'ebetso ea ho polishing e batla e se na phello ho bophara ba ka ntle ba molamu oa piston, mosebetsi oa ho sebetsa o hloka ho finyella boemo bo holimo pele ho chrome plating.Ka hona, hoa hlokahala ho eketsa ts'ebetso e ntle ea ho sila pele ho ts'ebetso ea chrome plating (ho sila ka mokhoa o nepahetseng ho ka boela ha ntlafatsa ho khomarela holim'a chromium. ).Ho ipapisitsoe le tlhahlobo e kaholimo, mekhoa e nepahetseng haholoanyane ea ts'ebetso ea molamu oa piston ke: ho otloloha-ho fetoha hantle ho fetoha hantle ho sila-chrome plating-polishing.

Q6: Ho belisoa ha molamu oa piston oa pneumatic cylinder ke eng

A: Nakong ea ho reteleha, lesoba le bohareng le phethang karolo ea ho beha boemo le tla bontša tekanyo e itseng ea ho apara.E le ho netefatsa molao-motheo o kopaneng oa li-benchmarks, lesoba le bohareng le lokela ho fokotsoa pele le sila ho netefatsa boleng ba ts'ebetso.Ha ho sila, ho sila teko ho lokela ho etsoa ka selikalikoe se ka ntle haufi le qetellong pele, 'me ho sila ha molamu oa piston ho ka etsoa feela ha boemo ba ho matha bo finyella litlhoko tsa ho sebetsa.Ntle le ho ntlafatsa ho nepahala ha dimensional, mokhoa o motle oa ho sila o boetse o hloka ho fumana mafika a holimo holim'a mochini o entsoeng ka mochini ho ntlafatsa kamano ea li-ion tsa chromium nakong ea ts'ebetso ea electroplating.E le ho etsa bonnete ba hore botenya ba chromium plating layer ea piston rod ea ho qetela bo tšoana, bokaholimo bo ka morao ka mor'a ho sila hamonate bo lokela ho ba haufi le bokaholimo ba bokaholimo ka mor'a hore chromium plating le benche.Haeba ho hlokahala hore bokaholimo ba molamu oa piston bo be bo phahameng, joalo ka Ra <0.2 μm, e lokela ho ba hantle fatše.Eketsa mokhoa o motle oa ho sila kapa oa ho bentša ka mor'a ho sila.